WHY?

Why replace a Bicycle Chain? A bicycle chain can be very efficient. This is a favourite online magazine debate. I want to answer a few questions that are missing. Why did OLSEN Bikes develop our Bikes around Belt-drive? If belt-drive is so good why don't other bicycle brands develop bicycles for belt-drive? Can I modify a normal bike frame to run a belt?

Belt vs Chain:

Tests have reported efficiencies as high as 98.6% However remember tests need to be carried out in a "controlled" clean laboratory environment, so that accurate measurements can be made. This does not sound like the real-world cycling, let alone UK Mountain Biking or even Gravel riding.

How does a BELT compare to a CHAIN?

Gates and Universal Transmission’s in Germany have conducted several tests with Global bike tourist Alee Denham. Remember that this is a single speed set up on a machine in a laboratory environment. You will find this article here:

There were some unusual results:

• Higher belt or chain tension was found to be more efficient.

• There is very little differences (0.5%) in output between the chain and belt.

• However, when both drivetrains have done some miles and are worn, this is where the belt becomes more efficient.

• A worn chain drive is about 4% less efficient than a worn belt drive.

This is because chains stretch. Gates belts do not. This goes back to the first point, a drivetrain under high tension is more efficient.

Experience from the REAL World:

Chains have links that rust, trap mud, water, and grit, and must be oiled. Remember that a derailleur chain drive system has more than 98.6% losses with its crude forever changing chainline. Gates Carbon Drive runs clean and sheds water, mud, and grit. Is there a winner to the belt vs chain test?? That depends on whether you are looking at results from the Lab or from the Real World. In real-world conditions, belts are the clean and simple winner.

Alternative Drivetrains to the Derailleur.

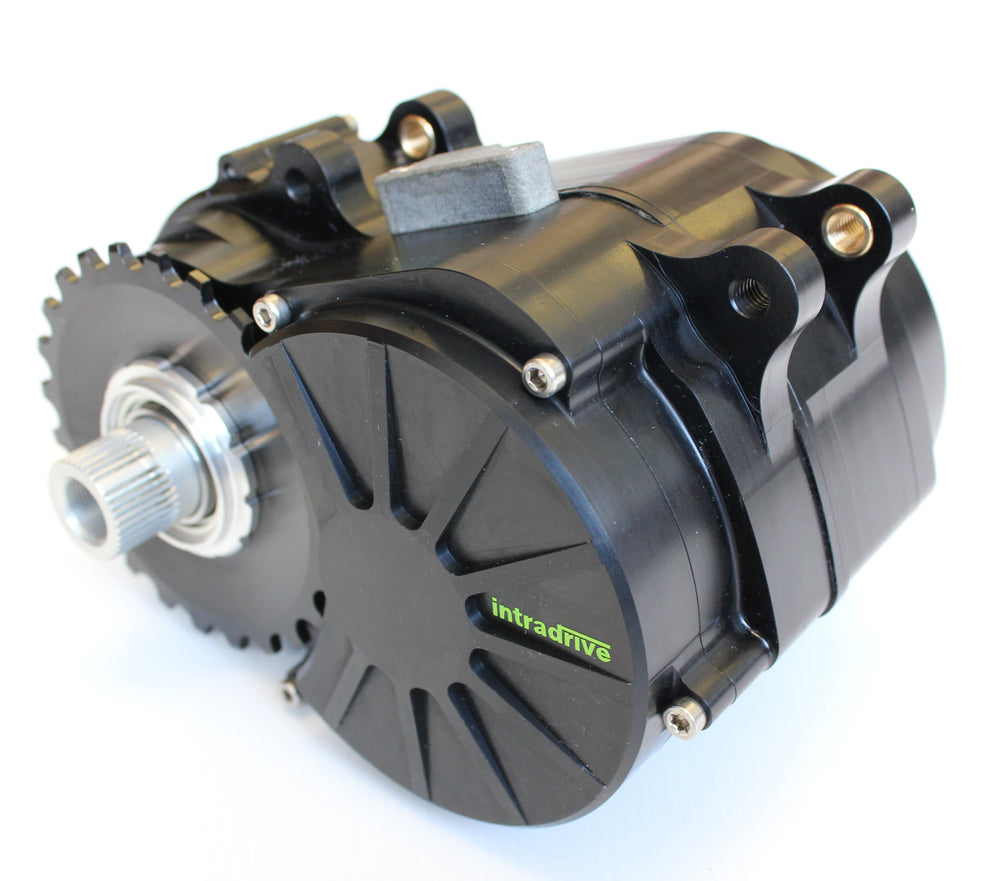

If you are after low maintenance drivetrain, forget the derailleur, you will be looking at Single Speed or Internal Hub gears, like Shimano Alfine, Rohloff Speedhub and Kindernay XIV. There are also other alternatives like the Pinion Gearbox and Bosch e-Bike drivetrains. There is no coincidence that all the above have also developed their systems to work with Gates Carbondrive.

If you are not convinced, there will be a winter when you wear out too many chains and sprockets in one season. This happened to me, and I have no looked back. Gates Carbondrive lasts over 2 winters so the investment pays itself back.

For all these drivetrains to work, frames need a method to tension the chain or belt. The only extra feature to make this frame belt-drive compatible, is a split seatstay or chainstay. If the engineer has gone to all the effort designing a chain tensioning system, then it does not take much to split the frame.

How did OLSEN Bikes go about designing their Belt-drive frames?

It’s all in the RocknRollout Dropout. A lot of things need to happen at a bicycle dropout. A nice derailleur dropout is satisfying to design and look at. A belt-drive dropout should be no different. Olsen Bikes have designed several adjustable dropouts, for both single-speed, internal gear hub and Pinion gearboxes. It was inevitable to design a belt-drive adjustable dropouts at some stage.

There are several things to consider when designing a frame for belt-drive:

• Belt Tensioning Method

• Splitting the Frame

• Frame Stiffness

• Chainring and Tyre clearance

• Rear Wheel Removal

Belt Tensioning Method:

• Belt-drive gives you the promise of set-and-forget drivetrain. There are several methods to tension the belt.

• Rear facing (track) dropouts - these are difficult to set the disc brakes.

• Rear sliding as above but designed to move the brake and the wheel maxle at the same time.

• Rear Swing dropouts - like the RocknRollout dropouts.

• Eccentric Bottom Brackets - these do not allow for micro adjustment and can slip.

Splitting the Frame:

• At OLSEN HQ I originally designed the RocknRollout dropout to work with Carbon our Carbon frames.

• I needed a method to split the frame, but also join the carbon frame as one structure. This is where the splice plate came from.

• The Splice plate fixes the rear chainstays to the seatstays.

• The M6 & M8 bolts then fix the dropout to be frame but also lock the whole structure in place.

• The RocknRollout dropouts allow the wheel to be dropped out vertically without needing to adjust the brakes or belt tension.

Frame Stiffness:

Frame stiffness is important to maximise rider output, but also to keep the beltline (or chainline). Olsen Bike use T47x92 bottom bracket standard to keep the chain stays as wide as possible. A 92mm BB shell moves the chain stay out almost 10mm on each side. This extra width ensures a stiff frame even with a flexible material like titanium.

Chainring and Tyre clearance:

T47x92mm also creates more room around the bottom bracket area for wider tyres. It was clear that there were 2 reasons to choose the T47x92 as standard.

Rear Wheel Removal:

The rear wheel needs to be removed to fix punctures. The design challenge is to have a dropout that needs no adjustment when removing or refitting the wheel. The dropout should allow the wheel to move the disc brakes at the same time.

Belt-drive Trouble Shooting and DIY Rumours:

Retro-fitted belt-drive:

Can You Modify Your Frame for Belt Drive? You could get your frame and get a frame builder to add a split joint in the frame, so that you can run a belt DIY style. However, you are likely to create a Flexible DIY Frame. 10years ago there were a few forums with DIY belt-drive riders doing this and some complaining consequently.

There is an alternative to splitting the frame. Veer have developed a belt that splits (see below); however, the same issues will happen with a DIY Frame. As mentioned above, a flexible frame will allow the belt to twist and ramp up the rear cogs, creating a popping noise.

If your belt makes a popping noise, either there is frame flex, or your chain-line is incorrect. Adjusting the chain-line and tension might help. However as mentioned above having a stiff frame, which has been designed for belt-drive is key to avoiding this frame happening.

Don’t Belts Destroy Bearings?

It is possible that a belt set to maximum belt tension could prematurely wear bearings. This is the other side of a frame that has been modified to fit a belt. To avoid the belt ramping and popping the belt tension will need to be higher than usual. This might seem okay, but you will stress and destroy hub and bottom bracket bearings.

OLSEN Bikes have been designed and engineered to have a wide stiff T47x92mm BB and chainstays to avoid sideways twisting and flex. Belt tension should be backed off to prolong bearings on other components. This is easy with a quarter turn of the tension screw.

Are belt-drive Gear Ratios are limited?

Olsen Bikes hold 2 front sprockets, 3 rear cogs and 3 belt lengths to suit our Bike builds. This should not be limiting at all for the purposes of touring and commuting. These are some gear ratios using 39T which are ideal for 29er mountain biking.

• 1.83 = 39:21T

• 1.77 = 39:22T

• 1.68 = 39:23T

• 1.63 = 39:24T

Are there other Belt-drive Companies?

Gates Carbondrive have had over 20years experience with belt-belt drive bicycles. Gates CDX Carbondrive completely dominates the belt-drive drivetrain market. There have been a few companies offering alternatives, however Veer is the only belt-drive alternative, that is readily available.

Veer has one bike advantage over Gates, the Veer belts split. The front sprockets have been designed for the commuting or road market as the front sprockets are larger. This is a good place to start your belt-drive journey. However long term the same issues that I mentioned above could happen under load. This might not be an issue for commuting, however climbing uphill takes another level.

Conclusion to the Belt-drive vs Chain debate?

When I started Olsen Bicycles, I wanted to make some belt-drive single speed bikes for riding in the UK. Much as I am an advocate for single speeding, I realise that it is not for everyone. I was conscious that customers would want gears. Designing a bike for a derailleur is very easy, as the chain is tensioned by the derailleur itself.

I wanted OLSEN bikes to explore more drivetrain versatility and belt-drive was a part of this. All the alternatives to derailleurs have a fixed chainline (or beltline).

Fixed beltlines are an advantage that does not get mentioned much, Plus-sized Tyres. 1x12 systems sometimes clips the side of a Plus Sized Tyre. With a fixed beltline maintenance on the chain or belt is less. Getting the frame stiffness and dropout design correct helps the drivetrain versatility.

With the RocknRollout dropout OLSEN Frames can run any drivetrain from Single Speed to Internal Gear Hubs. You could even do both by changing a wheel. Versatility is a key advantage and belt-drive is part of this. With Olsen Bikes you could effectively have 3 bikes in one. Derailleur one day. Single speed on day two. Internal Hub Gear on another. Only two of them can be belt-drive.

Our RocknRollout dropout tensioners mean you can run your Olsen exactly the way you want it and change your setup anytime you like. Single speed, belt-drive, derailleur, or internal hub gears - it’s your choice. One bike, many reasons.

Versatility and longevity - This is the Olsen way.